PLC Engine позволяет обрабатывать данные на производственных линиях.

Он соединяет контроллеры, устройства, SCADA системы и базы

данных различных производителей.

Он обрабатывает данные и передает их между подключенными

устройствами и другими системами.

Он собирает данные, управляет ими и создает обзоры для OEE приложений.

Все дополнительные данные могут быть обработаны через OPC. Это обрабатываемые данные

и все данные от подключенных контроллеров, устройств, систем OPC и баз данных.

PLC Engine является идеальным компонентом для использования в коммуникациях

Индустрии 4.0.

The configuration works in graphical style or with simple lists.

Lot of Wizards simplify this.

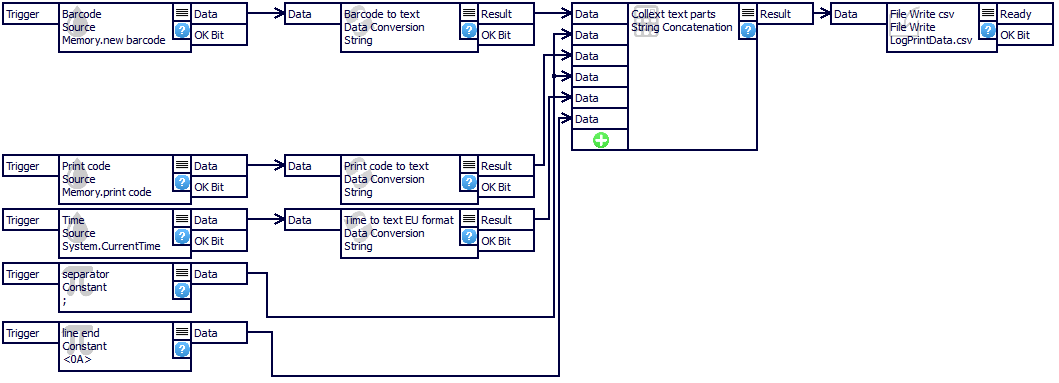

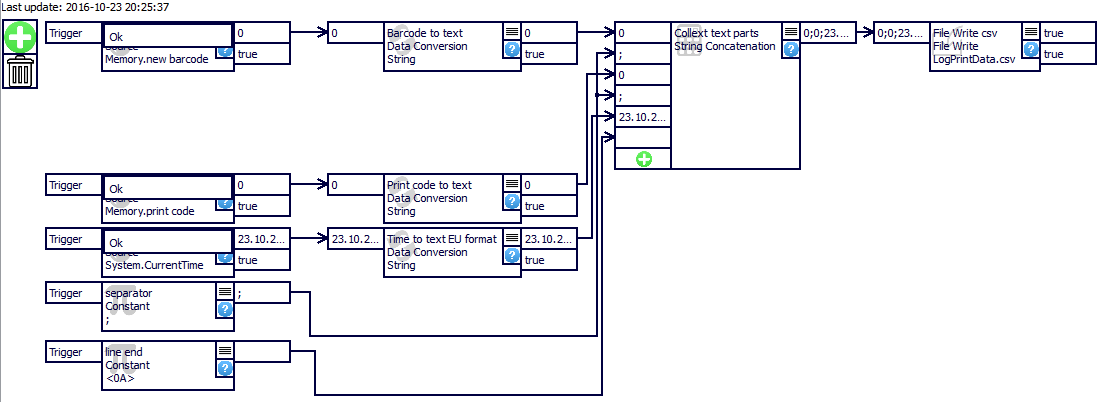

The example logs from barcode reader, adds a timestamp and writes both into a .csv file.

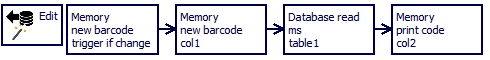

This example reads a barcode, gets the print data from a database and prints the result.

Diagnostics boost the startup in plants. Use Your smartphone or tablet and all of the status displays.

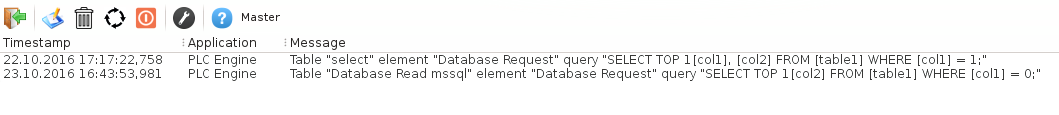

Журнал диагностики предназначен для более длительного сбора информации.

Максимальное количество OPC клиентов зависит только от используемых ресурсов. С 2014

года один ПК может обрабатывать несколько сотен соединений.

Все интерфейсы OPC работают локально на одном ПК или по сети.

в случае Classic OPC Classic, пожалуйста, не используйте DCOM по сети, но он

будет поддерживаться.

OPC UA поддерживает быстрый двоичный протокол. Безопасность поддерживается во всех вариантах. Поддерживается многоадресное обнаружение.

Элементы данных для доступа к данным поддерживаются до 200 000 штук каждый.

The OPC UA implementation conforms to the specification 1.05.

The OPC UA Standard Model is supported, some extensions exist.

The maximum single request and answerlen is 16m

The OPC UA Alarms & Conditions module is supported. This includes filters, history.

An internal discovery server is active on standard, it supports multicast discovery also.

It can be used as a global discovery server.

Alternatively an external discovery server can be configured.

Reverse connections are supported.

The certificate management GDS Push is supported.

The session timeout will be limited to one hour.

The server and client certificate will be renewed if the Tani self signed certificate is used. All other certificates remain unaffected on expiring.

The certificate validity is checked all 12h.

It will be renewed seven days before it expires.

Running connections will not be affected, new connections will use the new certificate.

AddNodes is supported with the following restrictions:

Machine models from the OPC Foundation or the VDMA directly can be loaded with its corresponding XML file.

The security certificate key minimum length are

Поддерживается трафик между различными интерфейсами OPC (туннелирование). Он будет использоваться для туннелей OPC DA.

All controllers will be connected over network. Often this is Ethernet, WLAN or other networks. All serial Ethernet and MPI Ethernet gateways for industrial controllers usage are supported.

Connections to devices and controllers are supporting network redundancy.

Double and triple redundancy can be selected.

Two redundancy operation modi are possible.

In dynamic redundancy any of the connections is working as master. If it breaks another connection becomes the master connection.

In static redundancy the first connection is the master. If it breaks another connection becomes the master. If the first connection works again it will become the master connection again.

The connections of the redundancy should work on different network adapters.The adapters need different IP subnets for properly work.

BACnet will be used over IP / UDP.

Maximum length of strings: 256 Byte

Status text elements are supported (state_text)

Supported charsets: UTF-8, UTF-16, Latin-1

Unions ("Choice") and structures ("Sequence") are existing for important values as trend, shedule, calendar, prioriry.

The trend data are offered as history data.

All unimplemented instances will not be shown.

Enum values are represented as UINT32. Some special enum are handled as bool.

Values in "Octet-String" and "Bit-String" can be written in whole only.

BBMD will be used during the connection establishing and the device search

if the devices do not be all in the same collision domain.

BACnet uses broadcast during ist connection establishing.

There are several procedures in BBMD:

COV represents the event subsystem of BACnet.

Events will be offered in browsing the variables, they will be subscribed.

If the device will send the data the event will be generated.

Because BACnet is working with UDP the COV receive can not be guaranteed.

Tani is offering an option: If no event will be received during the reconnection time from the configured connection it will be polled.

If the value did not change no event is send for this polling.

This mechanism was chosen to allow choosing the write priority via OPC without changing the read syntax for present-value property. This also allows writing NULL values via OPC.

The following object properties are implemented:

| Object Type | Property | BACnet Type | OPC Type | Remarks |

|---|---|---|---|---|

| all | all | BACnetObjectIdentifier | UInt32 | |

| all | all | Bit String | Array of Boolean | |

| all | all | Boolean | Boolean | |

| all | all | Character String | String | |

| all | all | Double | Double | |

| all | all | Enumerated | UInt32 | |

| all | all | Octet String | Array of UInt8 | |

| all | all | Real | Float | |

| all | all | Signed | Int32 | |

| all | all | Unsigned | UInt32 | |

| all | Change of State Time (16) | BACnetDateTime | DateTime | |

| all | Event Time Stamps (130) | Sequence of BACnetTimeStamp | Array of Structure "Timestamp" | |

| all | Object Type (79) | BACnetObjectType | UInt32 | |

| all | Time of Active Time Reset (114) | BACnetDateTime | DateTime | |

| all | Time of State Count Reset (115) | BACnetDateTime | DateTime | |

| Access Door (30) | Door Alarm State (226) | BACnetDoorAlarmState | UInt32 | |

| Access Door (30) | Present Value (85) | BACnetDoorValue | UInt32 | |

| Access Door (30) | Priority Array (87) | BACnetPriorityArray | Array(1..16) of Structure "UnsignedPriorityValue" | see section "Priority Array" |

| Access Door (30) | Status Flags (111) | BACnetStatusFlags | Array(0..3) of Boolean | |

| Analog Input (0) | Present Value (85) | Real | Float | |

| Analog Input (0) | Status Flags (111) | BACnetStatusFlags | Array(0..3) of Boolean | |

| Analog Output (1) | Present Value (85) | Real | Float | |

| Analog Output (1) | Priority Array (87) | BACnetPriorityArray | Array(1..16) of Structure "AnalogPriorityValue" | see section "Priority Array" |

| Analog Output (1) | Status Flags (111) | BACnetStatusFlags | Array(0..3) of Boolean | |

| Analog Value (2) | Present Value (85) | Real | Float | |

| Analog Value (2) | Priority Array (87) | BACnetPriorityArray | Array(1..16) of Structure "AnalogPriorityValue" | see section "Priority Array" |

| Analog Value (2) | Status Flags (111) | BACnetStatusFlags | Array(0..3) of Boolean | |

| Averaging (18) | Maximum Value Timestamp (149) | BACnetDateTime | DateTime | |

| Averaging (18) | Minimum Value Timestamp (150) | BACnetDateTime | DateTime | |

| Binary Input (3) | Present Value (85) | BACnetBinaryPV | UInt32 | |

| Binary Input (3) | Status Flags (111) | BACnetStatusFlags | Array(0..3) of Boolean | |

| Binary Output (4) | Present Value (85) | BACnetBinaryPV | UInt32 | |

| Binary Output (4) | Priority Array (87) | BACnetPriorityArray | Array(1..16) of Structure "UnsignedPriorityValue" | see section "Priority Array" |

| Binary Output (4) | Status Flags (111) | BACnetStatusFlags | Array(0..3) of Boolean | |

| Binary Value (5) | Present Value (85) | BACnetBinaryPV | UInt32 | |

| Binary Value (5) | Priority Array (87) | BACnetPriorityArray | Array(1..16) of Structure "UnsignedPriorityValue" | see section "Priority Array" |

| Binary Value (5) | Status Flags (111) | BACnetStatusFlags | Array(0..3) of Boolean | |

| Calendar (6) | Datelist (23) | List of BACnetCalendarEntry | Array() of Structure "BACnet.CalendarEntry" | |

| Device (8) | Last Restore Time (87) | BACnetTimeStamp | Structure "Timestamp" | |

| Device (8) | Local Date (56) | Date | Structure "Date" | |

| Device (8) | Local Time (57) | Time | Structure "Time" | |

| Device (8) | Object List (76) | Sequence of BACnetObjectIdentifier | Array of UInt32 | |

| Device (8) | Protocol Object Types Supported (96) | BACnetObjectTypesSupported | Array of Boolean | |

| Device (8) | Protocol Services Supported (97) | BACnetServicesSupported | Array of Boolean | |

| Device (8) | Segmentation Supported (107) | BACnetSegmentation | UInt32 | |

| Device (8) | System Status (112) | BACnetDeviceStatus | UInt32 | |

| Device (8) | Time of Device Restart (203) | BACnetTimeStamp | Structure "Timestamp" | |

| Event Enrollment (9) | Object Property Reference (78) | BACnetDeviceObjectPropertyReference | Structure "DeviceObjectPropertyReference" | |

| File (10) | Modification Date (149) | BACnetDateTime | DateTime | |

| Life Safety Point (21) | Present Value (85) | BACnetLifeSafetyState | UInt32 | |

| Life Safety Point (21) | Status Flags (111) | BACnetStatusFlags | Array(0..3) of Boolean | |

| Life Safety Zone (22) | Present Value (85) | BACnetLifeSafetyState | UInt32 | |

| Life Safety Zone (22) | Status Flags (111) | BACnetStatusFlags | Array(0..3) of Boolean | |

| Load Control (28) | Actual Shed Level (212) | BACnetShedLevel | Structure "ShedLevel" | |

| Load Control (28) | Duty Window (213) | Unsigned | UInt32 | |

| Load Control (28) | Expected Shed Level (214) | BACnetShedLevel | Structure "ShedLevel" | |

| Load Control (28) | Present Value (85) | BACnetShedState | UInt32 | |

| Load Control (28) | Requested Shed Level (218) | BACnetShedLevel | Structure "ShedLevel" | |

| Load Control (28) | Shed Duration (219) | Unsigned | UInt32 | |

| Load Control (28) | Start Time (142) | BACnetDateTime | DateTime | |

| Loop (12) | Controlled Variable Reference (19) | BACnetDeviceObjectPropertyReference | Structure "DeviceObjectPropertyReference" | |

| Loop (12) | Manipulated Variable Reference (60) | BACnetDeviceObjectPropertyReference | Structure "DeviceObjectPropertyReference" | |

| Loop (12) | Setpoint Reference (109) | BACnetSetpointReference | Structure "SetpointReference" | |

| Loop (12) | Present Value (85) | Real | Float | |

| Loop (12) | Status Flags (111) | BACnetStatusFlags | Array(0..3) of Boolean | |

| Multi State Input (13) | Alarm Values (7) | Sequence of Unsigned | Array of UInt32 | |

| Multi State Input (13) | Fault Values (39) | Sequence of Unsigned | Array of UInt32 | |

| Multi State Input (13) | Present Value (85) | Unsigned | UInt32 | |

| Multi State Input (13) | Status Flags (111) | BACnetStatusFlags | Array(0..3) of Boolean | |

| Multi State Output (14) | Present Value (85) | Unsigned | UInt32 | |

| Multi State Output (14) | Priority Array (87) | BACnetPriorityArray | Array(1..16) of Structure "UnsignedPriorityValue" | see section "Priority Array" |

| Multi State Output (14) | Status Flags (111) | BACnetStatusFlags | Array(0..3) of Boolean | |

| Multi State Value (19) | Alarm Values (7) | Sequence of Unsigned | Array of UInt32 | |

| Multi State Value (19) | Fault Values (39) | Sequence of Unsigned | Array of UInt32 | |

| Multi State Value (19) | Present Value (85) | Unsigned | UInt32 | |

| Multi State Value (19) | Priority Array (87) | BACnetPriorityArray | Array(1..16) of Structure "UnsignedPriorityValue" | see section "Priority Array" |

| Multi State Value (19) | Status Flags (111) | BACnetStatusFlags | Array(0..3) of Boolean | |

| Notification Class (15) | Recipient List (102) | List of BACnetDestination | Array() of Structure "BACnet.Destination" | |

| Schedule (17) | Effective Period (32) | BACnetDateRange | Structure "DateRange" | |

| Schedule (17) | Exception Schedule (38) | Sequence of BACnetSpecialEvent | Array of Structure "SpecialEvent" | |

| Schedule (17) | List of Object Property References (54) | Sequence of BACnetDeviceObjectPropertyReference | Array of Structure "DeviceObjectPropertyReference" | |

| Schedule (17) | Present Value (85) | ABSTRACT-SYNTAX.&Type | Structure "Any" | |

| Schedule (17) | Schedule Default (174) | ABSTRACT-SYNTAX.&Type | Structure "Any" | |

| Schedule (17) | Weekly Schedule (123) | Sequence Size(7) Of BACnetDailySchedule | 7 sub-objects ("Monday", "Tuesday", ...) of Structure "TimeValue" | Due to limitations of the BACnet protocol, you can only write complete days. |

| Pulse Converter (24) | Present Value (85) | Real | Float | |

| Pulse Converter (24) | Status Flags (111) | BACnetStatusFlags | Array(0..3) of Boolean | |

| Structured View (29) | Subordinate List (211) | Sequence of BACnetDeviceObjectReference | Array of Structure "DeviceObjectReference" | |

| Trend Log (20) | Client COV Increment (127) | BACnetClientCov | Structure "ClientCov" | |

| Trend Log (20) | Log Buffer (131) | BACnetLogRecord | Structure "LogRecord" | Accessed via "HistoryRead" function, "Read" shows only one record. |

| Trend Log (20) | Log Device Object Property (132) | BACnetDeviceObjectPropertyReference | Structure "DeviceObjectPropertyReference" | |

| Trend Log (20) | Start Time (142) | BACnetDateTime | DateTime | |

| Trend Log (20) | Stop Time (143) | BACnetDateTime | DateTime |

PLC Engine is a database client. It connects with user and password to the database.

The standard SQL statements INSERT INTO, UPDATE, SELECT, DELETE, FUNCTION and PROCEDURE will be used over the wizards. Other statements will be configured directly.

Supported are:

For using PLC Engine on a PC the locally installed databases can be used also.

On PLC Engine Device a My SQL database is installed. This database will be managed completely by PLC Engine.

The OPC Server contains a logger for diagnostics purposes during plant startup. The logger can be configured. The system load can be big if all controller data in big plants are logged.

Maximum number of configurable client connections: 4000.

Maximum length of a single item: 4GB.

Maximum number of elements each connection: 1 million.

Maximum number of elements (Items): 16 million.

Maximum OPC groups each connection: 100.

Maximum number of passive connection for each port is 999.

The OPC synchronous functions returning a bad quality immediately if the PLC

connection is not established.

Changes in controller configuration will be checked all 10 seconds if the PLC does not offer a mechanism for this check during write.

Fields can be up to 64K in length each.

Multi dimensional arrays can have up to six dimensions.

Fields can be up to 64K in length each.The maximum amount of configurable

logic tables is 60000.

The maximum length of one logic table is 4GB.

Maximum number of entries on a logic element 60000.

File operations can handle up to 64K in each request. Adding data to a file is limited only by the space on the disk.

Multi dimensional arrays can have up to seven dimensions.

The throughput will be mainly limited by the controller speed or the

reaction time of OPC applications.

Read requests to the controller will be optimized as much the controller is

supporting this. For that elements will be collected to blocks reading more

than requested, but not for inputs and outputs. These optimizing can be

affected by configuration separately for each connection. Optimizing can be

switched off, too.

Write requests to the controller are collected or handled in that order the

application did called the system.

On OPC all optimizing the individual OPC uses is supported.

The normal time in cyclic controller requests is 50ms.It can be faster if

the controller polling interval is set to zero.

Only data are sent to OPC which did change in the controller between two

read requests.

Логические таблицы построены для линейной логики. Петли(Loop) сделать невозможно.

Цепь последовательностей поддерживает не более 65535 шагов каждая.

Все логические элементы, функции которых могут давать сбой, поддерживают бит OK. Пользователь должен разобраться с этим, чтобы предотвратить неожиданное поведение во время выполнения.

Конструкции не могут содержать циклов/петли (Loop).

Размер структуры или переменной может составлять до 4 Гб.

The status diagnostics lists are supporting arrays up to 100 values each. If an array is longer than 100 values the first 100 elements are shown only. Writing this array is not possible.

The from version 1.8 existing field optimizings will prevent reading the long fields too often, the index is requested on standard only.This optimizing bases of the fact that the index does net changed too frequently.

The consumed computation time is depending on the load with communication.

Most the time it will be waited for controller data or OPC application

reaction.

All software is working with events. This maximizes the throughput and

minimizes the usage of computation time.

Multiple CPU are supported. Up to ten CPU will be used, the main work will

be handled by three CPU.

The installation does depending on the product install multiple parts

separately. On uninstall not all products are deleted automatically. But all

installed products can be deleted over the menu or the software part in the

system control manager.

The user settings will be preserved and not deleted during uninstall.

Type Auto-Import works for all client protocols that are able to use structures/enumerations and have online browsing functions. This includes:

These protocols have a fixed list of structures and don't need Auto-Import:

These protocols have online browsing, but don't use structures/enumerations:

All other protocols don't have online browsing.

Type Auto-Import is implemented in two steps:

Limitations:

Before Auto-Import Step 1, any types that have not been imported yet:

Before Auto-Import Step 2, any types that have not been imported yet:

After Auto-Import Step 2:

A client wishing to use a variable with a structure/enumeration type that has not been imported should

to trigger the type import. Only after completing one of these the structure type is available in the server.